-

Notifications

You must be signed in to change notification settings - Fork 0

Gutting the fish

Prepping a Big Mouth Billy Bass is no more difficult than cleaning a real fish and a lot less messy. And let us acknowledge those who have gone before us!

You'll need:

- Wire cutters

- Little rubber feet (sold at hardware stores)

- Breadboard. I used an older model of the full-size breadboard from Sparkfun

- Raspberry Pi (RPi)

- Power supply. Use a wall wart putting out close to 6 vdc. 12 volts is too much, 5 volts is possibly too little.

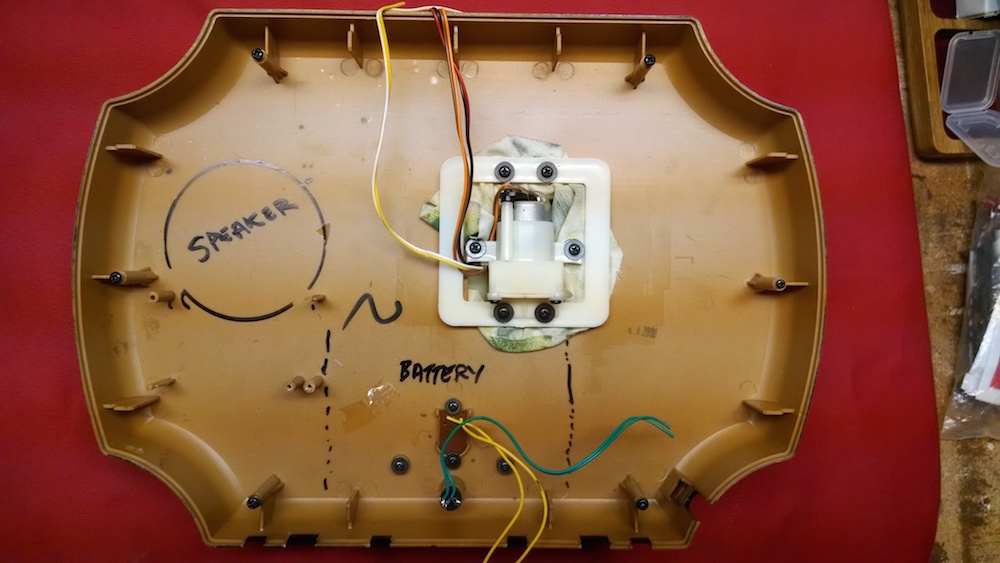

This first image shows the result of gutting the box. It's really that easy - take the screws out of the back of the fish, find the circuit board and clip all the leads as close to the board as possible. Throw away the board.

Don't worry about which wires control what motors - that can be figured out later. All of the other wires are self-obvious.

I used a sharpie to mark the placement of the battery case and speaker. This is to remind me not to place parts in a way that would block parts attached to the back.

Speaking of the back, here's a photo. Note the position of the speaker and battery compartment. I didn't clip the leads to the on/off switch or batteries - but I'm not sure I'll ever use them. Easier to leave them in place - at least for now.

Now that everything is cleaned out, there's room to put things back in. Let's start with the breadboard. Here's what it looks like in place.

There's a couple of things to note about this photo. First and most obvious is the placement of the breadboard across the top of the case. That keeps it out of the way of the battery compartment and speaker. I could have installed it vertically on the right side - but figured it would eventually work better if all wires ran to the top. In addition, I think the RPi will fit better on the right side - especially if I later decide to cut access holes in the case for USB or ethernet.

There's a couple of things to note about this photo. First and most obvious is the placement of the breadboard across the top of the case. That keeps it out of the way of the battery compartment and speaker. I could have installed it vertically on the right side - but figured it would eventually work better if all wires ran to the top. In addition, I think the RPi will fit better on the right side - especially if I later decide to cut access holes in the case for USB or ethernet.

You'll also note two little square things on the right side. Those are little rubber feet (LRB)...

I bought these at Hankin Hardware - they come four to a sheet, about 12 to a pack. The back of these feet is peel-off adhesive. I stick them on the plastic case and use them as screw attachment points. The two you see line up with the screw attachment points in the RPi. There are also LRB at each corner of the breadboard. A screw goes through the breadboard and into the LRB. Like so...

I bought these at Hankin Hardware - they come four to a sheet, about 12 to a pack. The back of these feet is peel-off adhesive. I stick them on the plastic case and use them as screw attachment points. The two you see line up with the screw attachment points in the RPi. There are also LRB at each corner of the breadboard. A screw goes through the breadboard and into the LRB. Like so...

Next - connect everything to the breadboard.

Note that my breadboard may be different from yours. On mine, it's easiest to think of this as four regions.

- The entire top row of holes - just the top line - 1 deep

- The top block of holes - 5 deep by the entire width

- The second block of holes - 5 deep by the entire width

- The entire bottom row of holes - just one deep

The top horizontal line of holes are connected. Likewise, the bottom horizontal line of holes are also connected. This is intended to supply power to everything in the middle.

The two middle blocks are separated by a trough. Each column of holes above the trough are connected to each other, and each column of holes below the trough are connected to each other. The top set of five pins is NOT connected to the bottom set of five pins. This is intended so you can straddle an integrated circuit across the trough and each pin of the integrated circuit has four breadboard holes to connect to the pin.

It doesn't matter what arrangement you settle on, but try to group things logically and leave some elbow room for other components. In this photo, from left to right, I've connected pushbutton, optical sensor, motor, motor, motor. (Don't fret about which motor is head, tail or mouth, we'll figure that in a minute.) Power comes in to common bus, positive across the top, ground across the bottom.

Note that on each motor, one lead is connected to the positive bus, the other lead is connected to a vertical breadboard line. Now you're set to figure out which motor is which - and amuse yourself.

Connect the red and black lines to a power supply (You'll see these on the far right side of the breadboard, top line is red, bottom line is black). Set up the BMBB so the flopping that is about to happen won't tip over your coffee. Activating the motors is as simple as running a patch from one of the motor breadboard lines down to the ground. In this case, current is flowing from the positive (top row) to the motor, then back to the breadboard top pin of five, the through the black patch wire (bottom pin of five in the same column as the motor connection) then to the bottom (ground) row of pins.

Connect the red and black lines to a power supply (You'll see these on the far right side of the breadboard, top line is red, bottom line is black). Set up the BMBB so the flopping that is about to happen won't tip over your coffee. Activating the motors is as simple as running a patch from one of the motor breadboard lines down to the ground. In this case, current is flowing from the positive (top row) to the motor, then back to the breadboard top pin of five, the through the black patch wire (bottom pin of five in the same column as the motor connection) then to the bottom (ground) row of pins.

Moving the top connector of the black patch wire to different columns will produce something like this...

<iframe width="560" height="315" src="//www.youtube.com/embed/rDOqp7PffsQ" frameborder="0" allowfullscreen></iframe>All I'm doing is placing the wire in one of the columns corresponding to the bmbb motor wire, pulling it out, then placing it in another column. Note that I'm using a 7.5 volt power supply - see the discussion about power supplies elsewhere.